Contact us for a free consultation

We hope that you will never be diagnosed with mesothelioma, lung cancer, or suffer a catastrophic injury, but if you are, contact us at Lipsitz, Ponterio & Comerford so we can begin the fight.

Call Today: 866-238-1452 or fill out the online form.

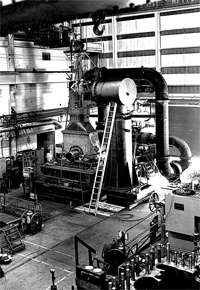

In 1912, the Clark Brothers Company constructed the Dresser-Rand manufacturing facility in Olean, New York, in order to replace a factory in Belmont, New York, which burned down. Originally, the Olean factory manufactured equipment for agriculture and sawmills. Because Olean was home to one the most productive oil fields in the world during the early 20th Century, the Clark Brothers expanded and began to manufacture equipment for the oil and natural gas industries. In 1938, the Clark Brothers merged with the S.R. Dresser Manufacturing Company, becoming the Dresser-Clark Company. In 1956, the company adopted the name Dresser Industries. After a merger in 1987 with Ingersoll-Rand, the company was renamed Dresser-Rand. Today, the Olean facility is a leading manufacturer of compressors for natural gas pipelines. Prior to the 1980s, asbestos-containing insulation and gasket materials were used during the construction of compressors. Exposure to asbestos can cause mesothelioma, as well as lung cancer and other asbestos-related diseases.

In 1912, the Clark Brothers Company constructed the Dresser-Rand manufacturing facility in Olean, New York, in order to replace a factory in Belmont, New York, which burned down. Originally, the Olean factory manufactured equipment for agriculture and sawmills. Because Olean was home to one the most productive oil fields in the world during the early 20th Century, the Clark Brothers expanded and began to manufacture equipment for the oil and natural gas industries. In 1938, the Clark Brothers merged with the S.R. Dresser Manufacturing Company, becoming the Dresser-Clark Company. In 1956, the company adopted the name Dresser Industries. After a merger in 1987 with Ingersoll-Rand, the company was renamed Dresser-Rand. Today, the Olean facility is a leading manufacturer of compressors for natural gas pipelines. Prior to the 1980s, asbestos-containing insulation and gasket materials were used during the construction of compressors. Exposure to asbestos can cause mesothelioma, as well as lung cancer and other asbestos-related diseases.